Composite Hose Assemblies

Composite Hose Assemblies

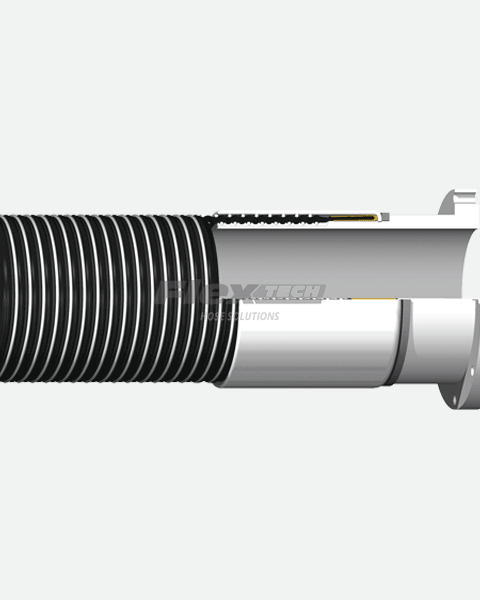

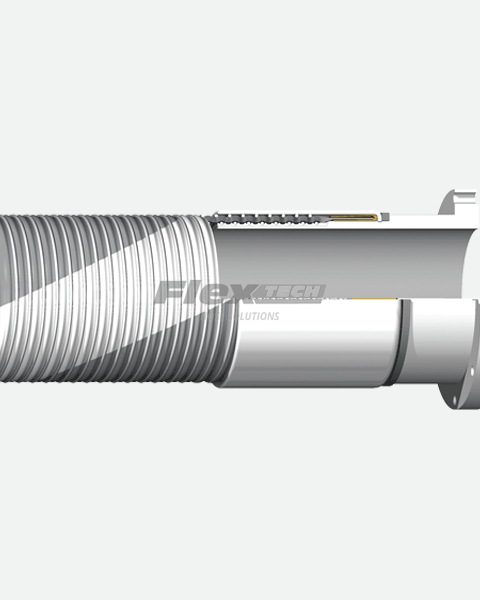

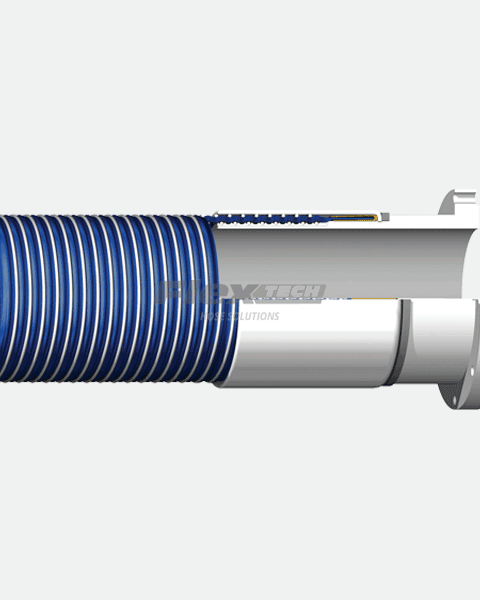

Flextech’s composite hose assemblies are manufactured from advanced composite materials in accordance with the strictest safety guidelines and quality standards. They provide optimum performance during critical and hazardous fuelling operations, chemical transfers, food transfer and loading of liquids. The blend of polymer liners, outer wire and polypropylene cover results in a composite hose with a vast array of benefits.

About our composite hoses

At Flextech, we take pride in being a leading supplier of high-quality composite hose assemblies. Composite hoses are a reliable solution for a wide range of industrial fluid transfer needs. Comprising multiple layers of materials, such as thermoplastics, fabrics, and metallic/non-metallic wires, these hoses offer a unique blend of flexibility, durability, and chemical resistance. With an unwavering commitment to quality, we deliver reliable and bespoke solutions that cater to the diverse requirements of industries like chemical processing, oil and gas, cryogenics, vapour recovery and more.

Our composite hose assemblies are engineered to excel in demanding environments and challenging industrial applications. Demonstrating reliability and durability in scenarios with things such as temperature fluctuations and diverse chemical compatibility, our composite hose assemblies have become indispensable components in a wide array of industries, including oil and gas, automotive, aerospace, cryogenics, and chemical processing.

What is a composite hose?

Composite hose assemblies are engineered using a "Mandrel Wrapped Principle" whereby multiple layers of thermoplastic fabrics and films are combined with metallic and non-metallic wires. These materials are chosen for their individual strengths, making the hose assemblies durable, flexible, and resistant to a wide range of chemicals and temperatures. As a result, they are suitable for handling diverse fluids and materials, making them a preferred choice in numerous industries.

Their medium weight strikes the ideal balance between easy handling and durability, resistant to wear, weathering and corrosion while their versatile operating temperature capabilities spanning -100°C to +150°C (-148°F to 239°F) enable further suitability in a wide range of applications. Typically, composite hoses will operate along working pressures between 10-14 bar.

Advantages of Composite Hose Assemblies

- Chemical Resistance: Composite hoses are designed to handle aggressive chemicals and solvents safely, thanks to their chemically resistance inner layers.

- Temperature Resistance: From hot to cryogenic conditions, composite hoses maintain their structural integrity, making them ideal for a wide range of industrial processes and environments involving hot and cold fluids.

- Pressure Resistance: Composite hoses have a good pressure resistance, typically ranging from 10 Bar to 14 Bar.

- Wide Operating Temperature Range: Engineered to perform well in diverse environmental conditions, these hoses have an operational temperature range from -100°C to +115°C.

- Corrosion Resistance: Composite hoses boast good resistance to corrosion, making them safe for transporting hydrocarbons like petrol, diesel, and fuel oils.

- Good Pressure and Vacuum Resistance: With durable reinforcement layers, composite hoses handle well both pressure and vacuum requirements.

- Lightweight, Highly Flexible, and Multi-purpose: These hoses offer ease of use, versatility, and efficiency across multiple applications.

- Robust: Composite hoses ensure the safety and reliability of fluid transfer operations.

- Relatively Inexpensive and Quick turnaround: Composite hoses offer cost-efficiency and are promptly available for various industrial requirements.

What can you use composite hose assemblies for?

Typical applications of our composite hoses are:

- Liquid storage tank terminals

- Refining

- Shipping/Ship owners & management

- Chemical plants

- Steel plants

- Paper, Paint & ink manufacturers

- Cryogenics

- Tank to Tank transfer hose

- Tank terminal hose

- Rail car refuelling hose

- Road tanker hose

- In plant transfer hose

- Chemical transfer hose

- Oil transfer hose

- LPG transfer hose

- Vapour recovery/return hose

- Formula 1 refuelling hose

- Jumper hose

Flextech's custom composite hose aseemblies

Composite hoses are completely customisable, with lengths available up to 40m and internal sizes from 25mm to 250mm. In addition to standard end connections such as lug type couplings, threaded couplings and flanges, gunmental fittings and camlocks, we also offer quick release fittings such as Dry Disconnect Couplings (DDC), Dry Gas Couplings (DGC), Dry Aviation Couplings (DAC) and Dry Cryogenic Couplings (DCC). Available in a range of materials with various BSPP, URT and threaded hose tails.

The most popular types of composite hose assemblies are;

- Oil Composite Hose

- Chemical Composite Hose

- Fuel Composite Hose

- Vapour Composite Hose

- Cryogenic Composite Hose