T7620 | FlexFlon (SG) Composite Hose

Enquire now to talk to one of our specialists.

Standards

- BS EN 13765 Type 3

- BS 5842: 1980

Description

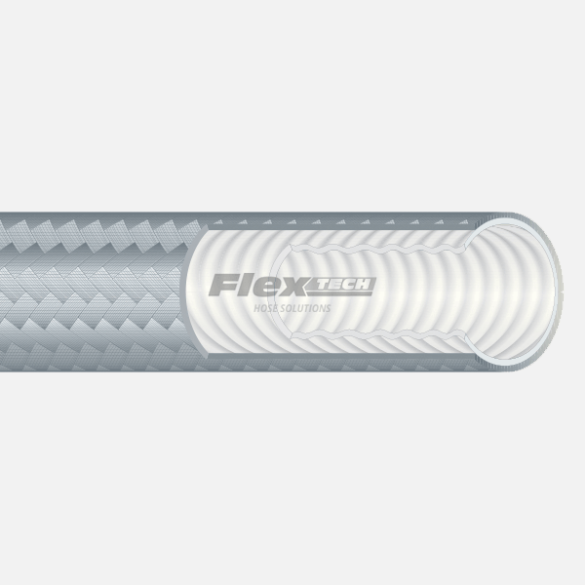

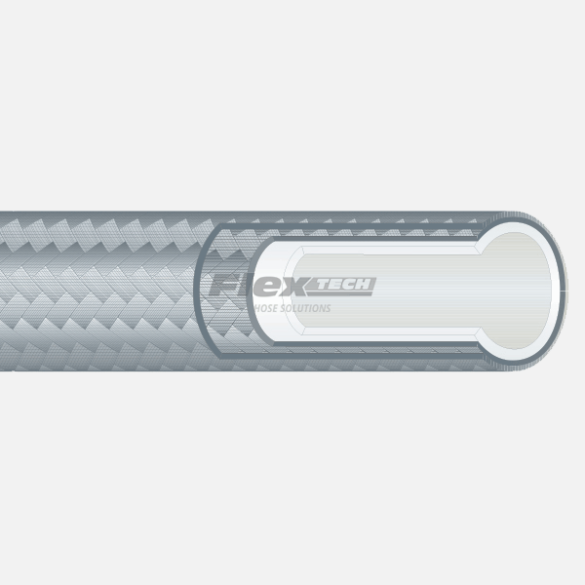

T7620 FlexFlon (SG) Composite Hose Assemblies are; 14 bar, tough, high strength, flexible composite hoses designed for general purpose petroleum transfer. Furthermore, these hoses are suitable for; fuels, fuel oils, chemicals, foodstuffs and general process applications. It is the material properties of the liner, fabrics and sealing films which enable FlexFlon composite hoses to meet the stringent temperature, pressure and vacuum service requirements found in specialist, chemical, petrochemical and general production applications.

Further information: Oil Composite Hose Assemblies by Flextech

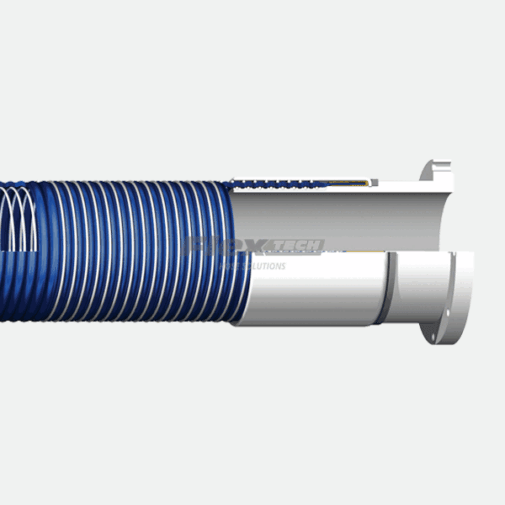

The different types of composite hoses can be easily paired with the type of media they are to convey as the components they consist of are foils and fabrics with varying properties. Polypropylene, polyamide, ECTFE, polyester, glass fibre or aramid fibre materials are available for the layers of fabric and film used in composite hoses. A reinforcing wire helix made of different materials such as zinc-plated steel, stainless steels and aluminium helps to protect the hose ensuring it is pressure and vacuum resistant. Our range of composite hose assemblies includes: chemical composite hoses (also for highly aggressive chemicals), oil and fuel composite hoses, liquefied gas composite hoses, concentrated alcohols composite hoses etc.

Working pressures up to: 14 bar

Temp range: -30℃ to 80℃

Key Features

- Excellent chemical resistance

- Good temperature resistance

- Very lightweight

- Very flexible

- Good pressure and vacuum resistance

Applications

Used for the conveyance of fuels, oils, chemicals, foodstuffs and general production applications in specialist, chemical, petrochemical, general production and food processing environments. Composite hoses are typically used in road and rail transport for loading and unloading of tank trucks or rail tankers, fitted on loading and unloading terminals, in port terminals, but also to convey substances in industrial processes.

Construction

Liner

PTFE

Reinforcement

316 stainless steel inner wire, high tensile strength mild steel outer wire. PTFE & ECTFE fabrics

Cover

Polpropylene films, layer of PVC, polyester cover