T4010 | Platinum Cured Silicone Tubing

Enquire now to talk to one of our specialists.

Standards

- 3-A Sanitary Standards

- BfR

- EC 1935/2004/CE

- EU Pharmacopia

- FDA CFR 21 177.2600

- USP Class VI

- ISO 10993-6

- IS0 10993-10

- ISO 10993-11

- ISO 9001:2008

- EU ResAP 2004 (4)

- BGA Class XV

- USP XXIV (87)

- USP XXIV (88)

- GB/T 21928-2008

Description

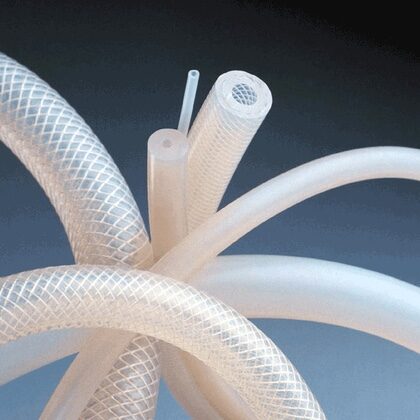

A smooth bore high purity platinum cured silicone tubing suited best for low pressure applications. This high quality tubing is manufactured in compliance with 21 CFR 177.2600 FDA and BGA Class VV, XVA, LIIA with a 60°/65° shore hardness, with no reinforcements.

This tubing is produced in the most versatile and flexible FED STD 209E Class 10,000 Clean Room manufacturing facility in Europe, using procedures controlled by ISO9001:2008 standards. Clean Room conditions are continually monitored to ensure a Class 7 standard is maintained.

The production facility used only produces Platinum Cured Silicone products ensuring there is NIL cross contamination.

Pharmaflex Silicone Tubing is packaged individually in double wrapped heat sealed polybags and then placed in a clean, white box ready for despatch.

Temp range: -60℃ to 200℃

Key Features

- Biopharmaceutical grade

- Autoclavable and sterilisable

- Sterlisation suitable with steam, argon and cobalt

- Tasteless and odourless

- Phthalate free

- Platinum cured extruded tubing

- Compatible with SIP and CIP regimes

- High transparency, no yellowing

- Excellent mechanical properties

Applications

Pharmaflex medical and pharmaceutical grade silicone tubing is suited for meeting the demands of practically any low pressure application.

Manufactured to fine tolerances (BS 3734), means the smallest silicone tubings produced are most commonly used as electri- cal sleeving, whilst mid-range sizes are generally used to carry fluids and powders within the food processing and pharmaceutical industries.

Construction

Liner

High purity platinum cured silicone tubing